Contact us for a price

DryLink is the market leading Dry Disconnect Coupling with the lowest spill rates.

Click Enquire Now or email drylink@actionsealtite.com

Enquire now

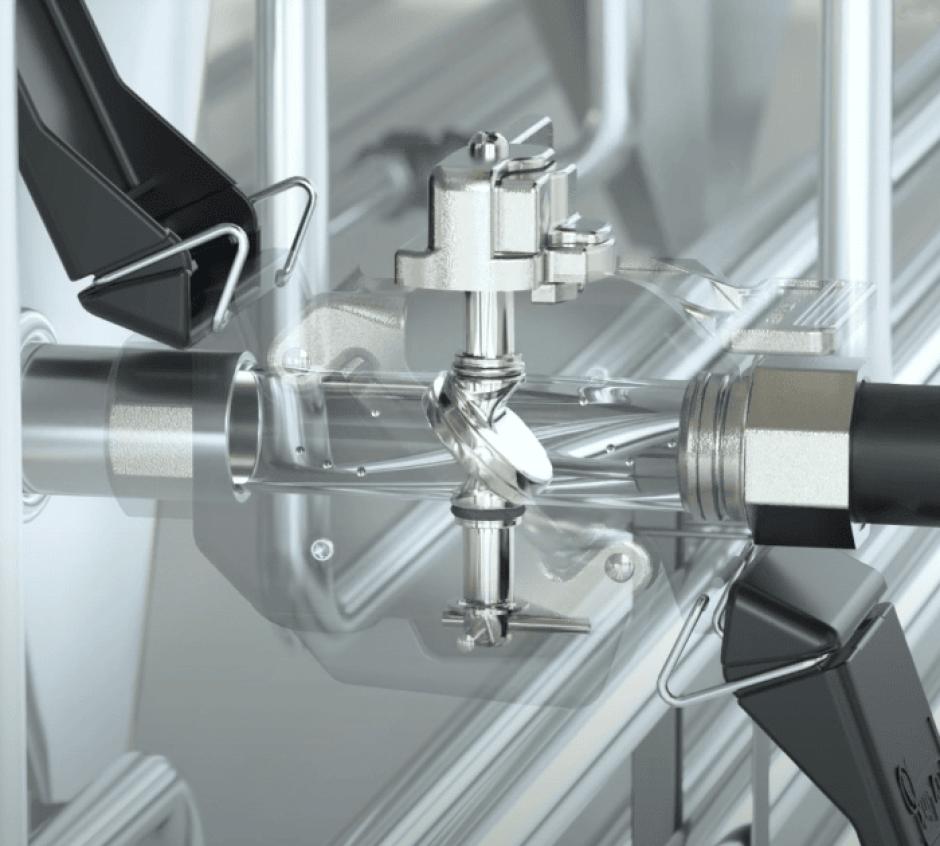

DryLink fittings feature a butterfly valve, rather than a poppet, plunger, or ball valve.

DryLink fittings do not have any Interior cavities, voids or springs which can promote the growth of bacteria through trapped media. This makes DryLink a true Sanitary dry disconnect fitting.

DryLink is the market leader of the dry break range of couplings and exclusive to Action Sealtite. It’s unique patented design means that the flow is controlled by one single handle, which is attached only to the coupler. The handle operates the adaptor valve as well as the coupler making it very quick to secure and easy to use. More importantly, it is the only true non-spill coupling available in the world.

“Independent, third party testing by Factory Mutual Research has verified that the 2” (DN 50) size Dry Link hose coupling assembly had only 1 to 2 drops of total cumulative leakage after a total of 10 connect/disconnect cycles. No other product comes close!” From DryLink website: https://www.drylink.com/faq.html

DryLink can be used in any application where a dry disconnection is required but is most commonly used in industries where fluids are hazardous, toxic, corrosive or flammable or if the liquid is of a considerably high value. Typical industries include chemical, pharmaceutical, cosmetics, printing, paints, soap, food and drink, hygienic, nuclear and microelectronics. Dry Link can be used on IBCs.

It is the most superior product available on the market today and this is due to the unique design:

All internal seals are spring-energized PTFE as standard

Couplings are offered in sizes 1”, 1.5”, 2”, 3” and 4” (DN 25, 40, 50, 75, and 100).

We also offer custom ½” and ¾” sizes.

Coupling ratings vary with size and seal materials. There are so many options; it’s best to call us with your requirements so we can guide you through what is available. Please call the team today on +44 (0)1235 512500

Dry Link “keyed” couplings are used in batch process plants and manifolds for preventing accidental cross-contamination of chemicals.

To discuss your options in full with an expert from our team, please call on +44 (0)1235 512500 or email sales@asleurope.com.

Contact Us